Checking Problem

How to resolved the checking problem in rotary molded(Digestive) biscuit.

RBS hosts its first Pretzel Training Seminar on February 3-4, 2026, offering hands-on learning on ingredient selection, mixing, baking, and optimizati...

Protein snack cracker is a crispy, plant-based 20% protein snack, a protein-rich alternative to conventional snacks for consumers looking for a fulfil...

In recent years, there has been a growing demand for healthy, gluten-free snacks in the food industry. One innovative approach to meeting this demand...

Effective partnerships will therefore remain essential in addressing these new challenges in order to deliver the next generation of high technology s...

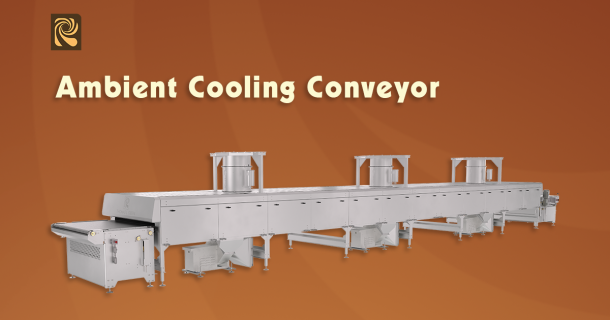

RBS has introduced a new ambient cooling conveyor that efficiently cools crackers before entering packaging in a more compact footprint.

The score is based on the number of created courses at BPA (150 points per course), the number of the lectures given at BPC (100 points per lecture), published articles (20 points for every approved article in Our Experts category ), number of resolved questions (10 points for every resolved question) and the number of asked questions (5 points for every asked question). The list is showing only top 10 biscuit industry experts.