Turn-key dosing, vertical bagging and cartoning solution for naked or pre-wrapped biscuits

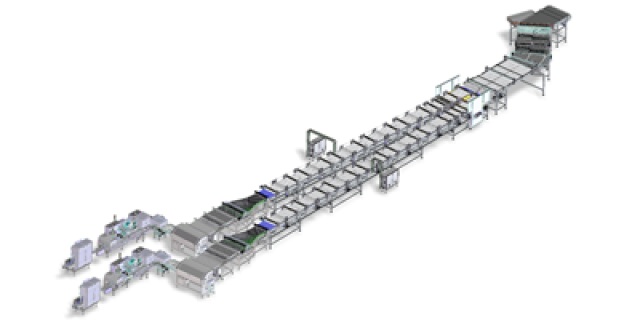

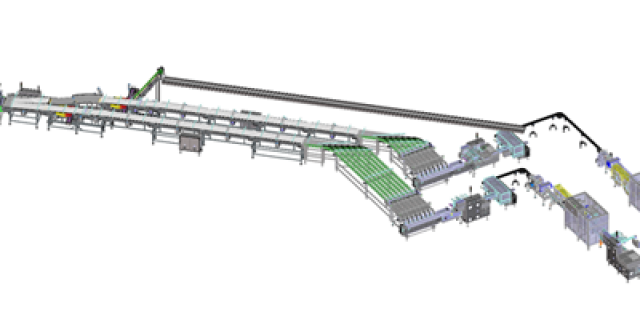

IMA FLX is glad to offer the full solution taking your products from the process line exit (i.e. cooling tower) all the way down to the weighing system, packaging machine and the end of line equipment.

High speed turn-key system from IMA Ilapak and IMA Ciemme for dosing (weighing or counting), bagging and cartoning a wide range of biscuits and bakery products, both naked or pre-wrapped, in a variety of pack styles and weights

Having one single partner for your complete system is definitely a great advantage during the complete lifetime of your packaging line.

Description

IMA Ilapak weighing & VFFS bagging: Vegatronic 6000 and WA 16-10

A wide choice of multi-head weighers is available to handle your products in the most suitable way and maximize the system performance such as gentle handling execution to minimize breakage and damages, high speed specs for fast packaging systems, memory bucket solutions for handling multiple products, counting and weighing mode flexibility are a few examples of what we can offer.

Same versatility is available on IMA Ilapak VFFS machines, able to provide you with the best solution for your needs.

Intermittent and continuous baggers depending on your speed requirements, entry level or top range machines based on your budget, compact machines or XL to fit your bag size range and a number of pack styles available such as pillow, gusseted bags, block bottom, Quattro, Flexcan, Doy-style and even more.

This line features IMA Ilapak WA 16-10 slim weigher and Vegatronic 6000 VFFS machine and is specifically conceived for high speed application thanks to the short drop height on the weigher and continuous film motion on the bagger but at the same time it suits brittle products as well being so compact.

The vertical bagger is available in painted machine frame and stainless steel and can be equipped with different solutions to enhance the OEE efficiency, in fact film or size changeover can be executed in a rapid manner thanks to a forming tube fitted on a swivel arm and a very ergonomic film splicing table that can be vacuum assisted, heat assisted, dual reel holder and automatic splicer as well.

IMA Ciemme AC continuous cartoner

IMA Ciemme AC is a continuous cartoner machine designed to handle a wide range of carton formats allowing a gentle product loading at high speeds.

Bags, arriving from vertical form fill seal (VFFS) machine, are conveyed to trap loaders (“stars”) to drop products into machine lug infeed conveyor. The AC uses a 3-head rotary feeder, with positive pre break, for maximum speed and efficiency, a barrel loader for smooth introduction ending with glue flap closing. The robust, low maintenance, easy cleaning, full visibility design ensures a high operational efficiency and long lifetime resulting in low operational cost. Touch screen controls deliver ease of use and step by step changeover for reliable and repeatable operations.

IMA Ilapak weighing & VFFS bagging: Vegatronic 6000 and WA 16-10

- Open Frame design

- Hygienic execution

- Great accessibility

- Compact footprint and overall height

- Wide range of pack styles

- Can handle laminated films, LDPE, compostable and recyclable films (paper-based)

IMA Ciemme AC continuous cartoner

- Layout: Modular and specular design, easy access

- Wide Format range: Wide range of products, patterns and case styles provides flexibility for current and future needs

- Changeover: Quick, reliable format changeover using customized format kits and spindle adjustments

- Quality: All bought-in components are sourced from recognized industrial suppliers. Each machine passes a detailed and through in-house tests (Pre-FAT)

Highly flexible design: The modular design allows to load products in single, multi-row or multi-layer collations and sideloads them standing or flat into orrugated or solid board.

Technical Data:

IMA Ilapak weighing & VFFS bagging: Vegatronic 6000 and WA 16-10

|

Speed |

Up to 160 ppm |

|

Max bag width |

280mm |

|

Max film width |

630mm |

|

Product size |

Up to 85mm (greater is feasible with larger bucket weighers) |

IMA Ciemme AC continuous cartoner

|

Line Speed |

|

|

up to 200 products/minute |

|

up to 200 products/minute |

|

Case size |

300x320x85 mm |

IMA Ilapak weighing & VFFS bagging: Vegatronic 6000 and WA 16-10

- Auto film reel splicer‘’Quattro bags’’ system

- Ultrasonic sealing system

- Special longitudinal system for paper films

IMA Ciemme AC continuous cartoner

- Stainless steel construction

- Unique infeed systems / loaders for specific products

- Ergonomic low level carton magazine

- Extension of carton magazine

- Tuck-in flap closure

- Overhead compression unit

- Multiple machine pitches

- Open flap detection with reject

- Fully automated format changeovers

- Centralized lubrication (manual or automatic)

- Labeller / Printer integration

- Spare parts kits