Packaging solution for biscuits in Doypack and cardboard display box

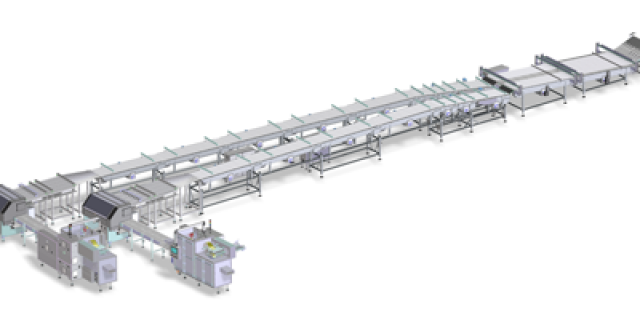

This automatic biscuit packaging line consists of:

- IMA Ilapak LUX DC High speed HFFS Doypack machine with a unique dual motion system composed of an intermittent module for pouch forming and a continuous module for product filling.

- IMA Ciemme WA series case packers, capable of packing a variety of products into one-piece wrap-around or two-piece display box (tray + lid) cartons.

LUX DC Stand-up Doypack machine:

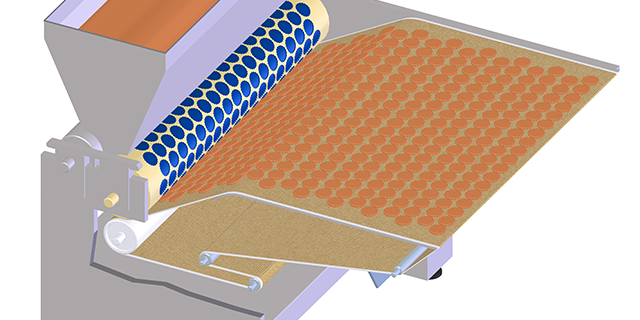

The LUX DC 235 -150/8 has been designed to form flat film roll stock into high quality stand-up Doypack with fully integrated filling solutions for small biscuits, filled biscuits, sandwich biscuits and snack biscuits. Given its versatility, the LUX machine is suitable for a wide number of bag dimensions and filling volumes, as well as the possibility to equip the Doy pouches with re-closable zipper, shaped round corners, easy open tear notch and hole punch.

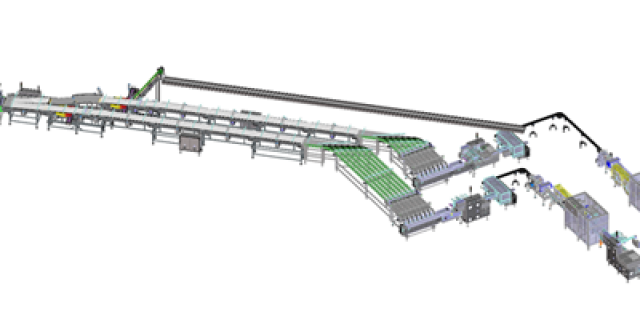

WA series case packer:

The case packer machine is fitted out with a double infeed system to receive both Doypack and bags arriving from two different upstream equipment. Pre-packed products are fed separately (Doypack) or grouped (bags) to a vertical track collation system which receives the products flat and transports them standing thanks to the infeed and pockets design. Once extracted from the collation unit, the grouping is positioned on the tray blank (or wrap-around); the carton is folded around the entire grouping and secured with hot melt glue. A dedicated modular unit provides to fold the lid over the grouping and close it with hot melt glue (display-box).

LUX DC Stand-up Doypack machine:

- Rotary servo punch

- Servo controlled forming triangle

- Dual motion to control the film tension and to actively keep the top fins aligned

- Dedicated eye mark reading sensors for the forming and cutting units

- Increased precision of pouch positioning during the sealing operation and reduced tolerance of single pouch cutting intersection, by elimination of eye mark reading errors accumulation

- Continuous and rotary motion cutting system

- Increased speed of the unit, format registration for pouch width controlled by the PLC and elimination of multiple units requirement

- Continuous motion dosing unit

- Increased dosing time for higher production speeds, high volumes or difficult product dosages

- Pouch extraction carousel at machine outfeed

- Multi-head weigher integrated

WA series case packer:

- Layout: Ergonomic and versatile configuration, one-piece (wrap-around) or two-piece (tray + lid) cartons, single or double magazine to allow both production on the same machine

- Wide Format range: Wide Flow pack and box size range provides flexibility for current and future customer needs.

- Changeover: Quick, reliable format changeover customized format kits and spindle adjustments

- Quality: All bought-in components are sourced from recognized industrial suppliers.Each machine passes a detailed and through in-house tests (Pre-FAT)

- Highly flexible design: The modular design allows to load products in single, multi-row or multi-layer collations and sideloads them standing or flat into orrugated or solid board.

LUX DC Stand-up Doypack machine:

Min-Max pouch width

120-235 mm

Min/Max pouch height

190-330 mm

Min/Max pouch gusset height

15-60 mm

Target output - up to 400 grs

150 ppm

Target output - up to 800 grs

110 ppm

Filling stations

8

Wrapping materials:

Suitable heat-sealable films, plain or co-extruded polypropylene (PP), laminate films (eg. OPP+PE) as well as cold sealable films of suitable quality. NEW! Sustainable and eco-friendly materials such as paper-based, recyclable and compostable films.

WA series case packer:

Line speed

15 boxes/minute

Case size

400x300x400

LUX DC Stand-up Doypack machine:

- Integrated top cooling

- Possibility to discriminate between good and rejected pouches, keeping control on the pitch between the released bags on the outfeed belt, allowing for an orderly disposition to a potential inline check weigher.

-

WA series case packer:

- Stainless steel construction

- Open flap detect and reject system - unsealed cases

- Fully automated format changeovers

- Centralized lubrication (manual or automatic)

- Labeller / Printer integration

- Spare parts kits