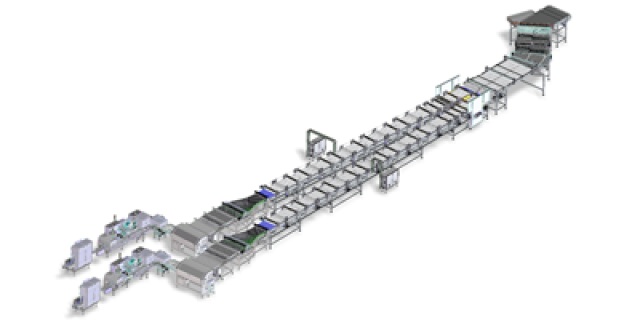

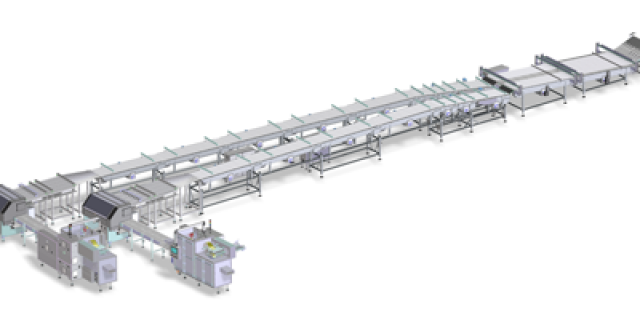

Flow wrapping and cartoning line for biscuits

IMA Ilapak primary packaging

The line is capable of packing cookies in various configurations, from individually wrapped biscuits to twin-packs in which the biscuits are in a single stack and packs of four biscuits in two stacks, at speeds of up to 500 pieces per minute. Size changeovers are executed in a matter of minutes, thanks to interchangeable product guides, a removable stacking device and an interchangeable sealing head.

The wrapper incorporates in-built quality control for detecting and rejecting broken products prior to wrapping, a ‘no product no bag’ function and automatic reel splicing for continuous operation.

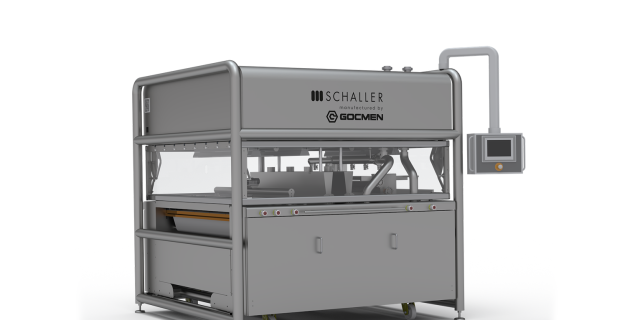

IMA Ciemme secondary packaging

Flow packs, arriving short side leading from one lane are spaced and conveyed (through specific accelerating belts) to a vertical track collation system that receives and indexes the products which are then picked up (in tracking) by a Delta robot (with a specific vacuum end effector) and placed in the carton boxes.

The line combines different Ciemme equipment including a high-speed double-head carton former (lock) and a single head carton former (glue) to satisfy a customer’s specific request; to end one high speed 90° carton closing (glue) complete the system.

In order to provide a complete system solution, we supply up and down-stream equipment for primary packaging, conveyors, check weigher, metal detector as well as printer/coder/reader modules.

120 carton boxes per minute can be erected, loaded and closed and up to 240 products per minute can be picked and placed with a single 3-axis robot.

Nowadays customers need more than just a separate stand-alone solution: they need an overall concept that incorporates their products into planning and every production step.

Ciemme together with all the IMA Companies support the customer as partners with comprehensive turnkey solutions.

IMA Ilapak primary packaging

- Hygienic design

- Modular construction design

- Maximum flexibility à can handle different biscuits sizes and configurations

- Interchangeable sealing head

- Removable stacking device

IMA Ciemme secondary packaging

- Layout: Compact and versatile configuration. The individual machines are coordinate to set up a complete harmonized system.

- Wide Format range: Wide Flow pack and box size range provides flexibility for current and future customer needs.

- Changeover: Quick, reliable format changeover using customized format kits and spindle adjustments

- Quality: All bought-in components are sourced from recognized industrial suppliers.Each machine passes a detailed and through in-house tests (Pre-FAT)

- Highly flexible design: Load flow pack into boxes horizontally (lay flat) or vertically (on edge) with fast changeovers if needed (aading specific modules)

IMA Ilapak primary packaging

Flow wrapping speed

up to 500 ppm (single product) with rotary jaws

Product size (single biscuit)

- Max length

up to 150mm

- Max width

up to 100 mm

- Max height

up to 15 mm

Wrapping materials

Suitable heat-sealable films, plain or co-extruded polypropylene (PP), laminate films (eg. OPP+PE) as well as cold sealable films of suitable quality. NEW! Sustainable and eco-friendly materials such as paper-based, recyclable and compostable films.

IMA Ciemme secondary packaging

Line speed

- Input

240 flowpacks/minute

- Output

120 Boxes/minute

Case size

300x250x110 mm

IMA Ilapak primary packaging

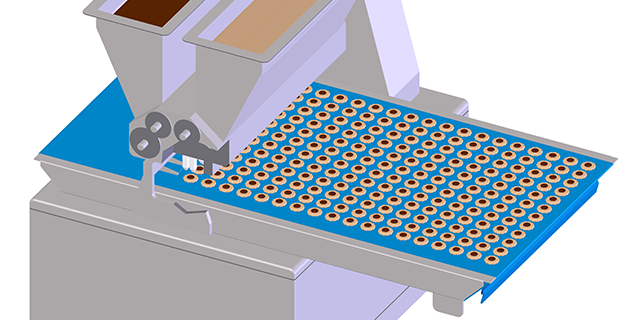

- D-cam jaws

- Row distribution system to feed the primary wrapping station

- Longitudinal ultrasonic sealing system

- Dedicated devices to run new sustainable generation materials (paper-based, recyclable, compostable)

IMA Ciemme secondary packaging

- Stainless steel construction

- Special infeed belts for products on edge (loading unit)

- Double or Triple-head configuration (carton former)

- Open flap detect and reject system (carton closer)

- Centralized lubrication (manual or automatic)

- Labeller / Printer integration

- Spare parts kits