Automatic Packaging Line for Crackers on Edge

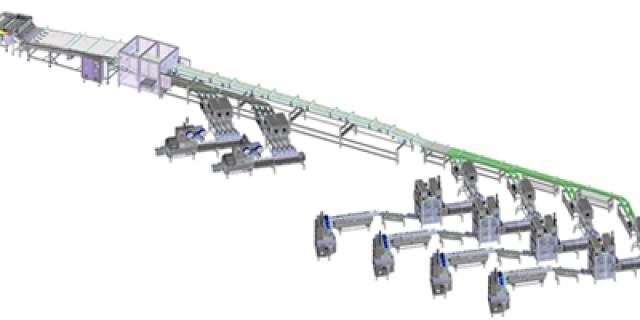

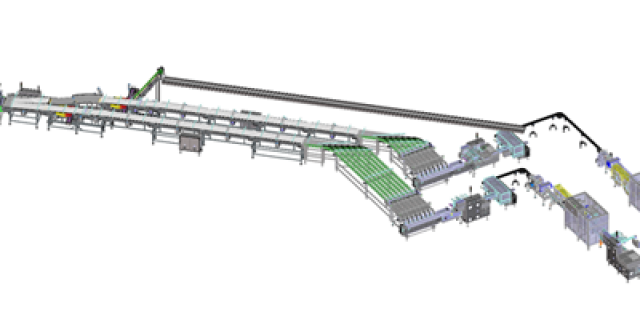

The automatic feeder Flowbiscuits dosing system receives products from vibrating channels, separates the pre-established quantity of crackers by volume and deposits them into a barrette infeed conveyor.

The loading robot forming a gradual and soft insertion on the infeed of the Flowpack machine JAGUAR BS RS ON EDGE for primary packaging.

The Edge Folding Unit purpose of folding the edges of the cross seals of the flowpack to produce a square pack and facilitate the next secondary packaging.

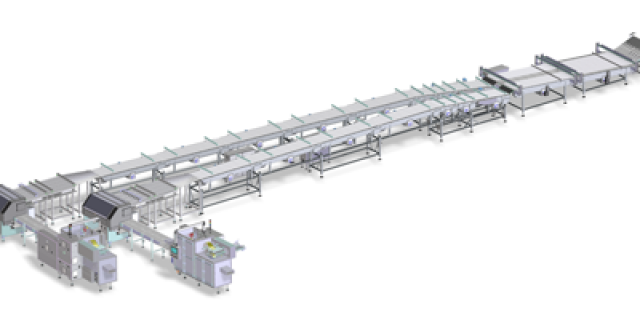

With the feeder Flowfeed High Tech the products arriving in a single line are collated and gently accumulated and then phased into the infeed conveyor of the JAGUAR BS RS flowpack machine for the multipacks.

Highlights:

- Hygienic design

- Modular construction design, easy access

- Maximum flexibility: can handle different crackers sizes and configurations

- Fully integration of systems providing reliability and flexibility

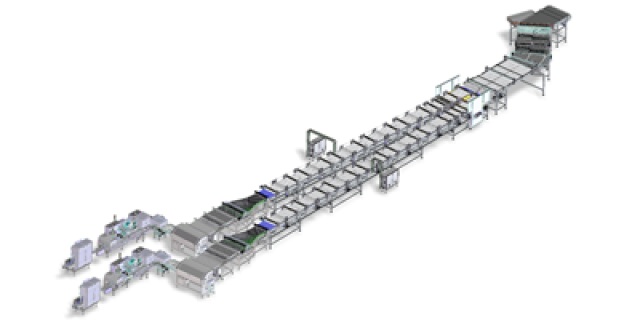

Technical Data:

|

Primary Packaging |

|

Secondary Packaging - Multipack |

||

|

Primary Packaging per min |

up to 340 |

|

Secondary Packaging per min |

up to 140 |

|

Size of Primary Packaging: |

|

|

Size of Secondary Packaging: |

|

|

Max length: Max width: Max height: |

up to 100 mm up to 95 mm up to 64 mm |

|

Max length: Max width: Max height: |

up to 412 mm up to 190 mm up to 66 mm |