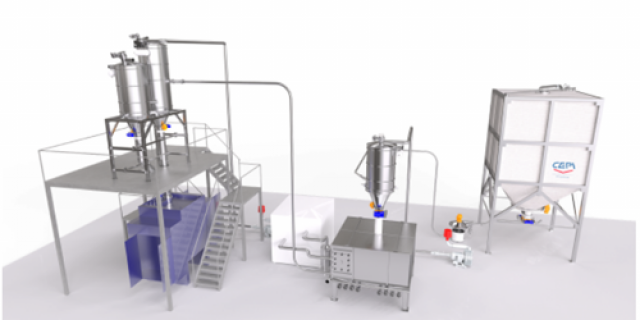

Cold fat dosing

Cold dosing of fat, margarine and butter in paste form, through a closed system that allows total control on the temperature of the product before and after dosing.

Cold fat dosing stabilizes temperatures and preserves the organoleptic characteristics of ingredients such as fat, margarine and butter. Dosing in paste form achieves a product that is easier to amalgamate with the dough, and is especially suitable for the production of biscuits, cakes and other confectionery. It also ensures time saving, higher hygiene in the storage and production rooms and accurate dosing due to absence of air in the pipe.

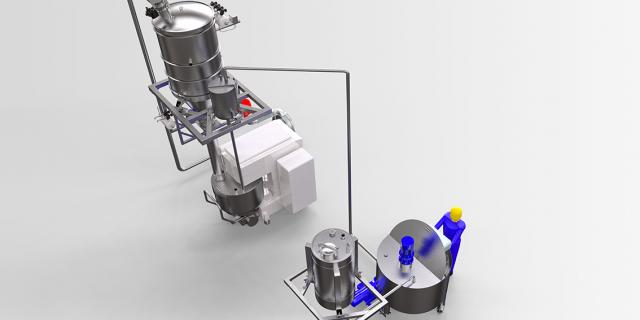

The process includes manual loading of blocks in a weighed double jacket tank and conveyance to the discharge point through worm pump and jacketed pipe. The product is then dosed in bowl through a massic flow meter at the same temperature of the block initially inserted in the system.

Features & Technologies

-

Easier to amalgamate with the dough

-

Metering in paste form

-

Double jacketed tanks with motor driven agitator

-

Temperature control

-

Dosing pump

-

Flow meter

-

Weighing in real time, integrated automation and full traceability