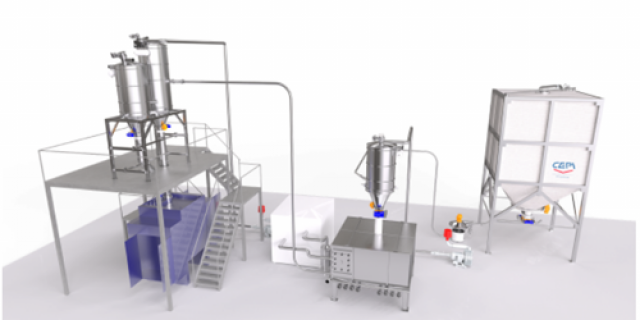

Silbox

Indoor silos made of panels, in stainless or aluminum steel. Modular and extendable, they offers the highest flexibility in the storing of all flours and powdered ingredients.

Silbox can be equipped with fluidized bed for a complete emptying of product by the first in first out principal (FIFO), full traceability and top waste efficiency. Extraction with vibrating cone for abrasive products such as sugar and salt. Special solutions are available for cous-cous and short pasta.

The flour oxygenation operated by the fluidized bed leads to a crucial improvement in the quality of the flour, with a faster but natural maturation that improves the flour’s rheological properties without using additives. Fluidized flour is much better for breadmaking, with better responses to all treatments from dough preparation to fermentation. The dough is more elastic and easier to work. It absorbs water more easily and keeps gas in more easily during leavening. Bread made from well oxygenated flour is softer thanks to a more alveolar product, and more digestible as oxygenation allows for longer leavening.

Hygienic design and ATEX conform, Silbox can be assembled locally during installation.

Features & Technologies

-

Antistatic Trevira fabric

-

Structural flexibility and balance between product and environment

-

Fluidization and accurate FIFO management

-

Flour oxygenation

-

Equipotentiality and filtering roof

-

Safety system against overpressure and depression during storing

-

Safety system CEPATIC against overpressure and depression during loading

-

Dosing with ATEX conform butterfly valve, rotary valve or feed screw

-

Weight control in real time, integrated automation and full traceability