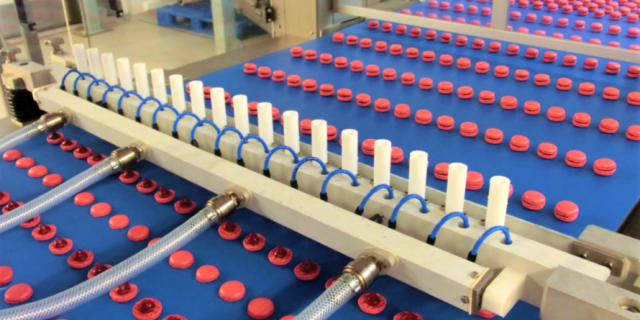

Sandwich Biscuit Rework System

The system for the liquid recovery of sandwich biscuit scraps is the latest innovation to our technology. Scraps are broken inside a stainless steel tank with agitator and mixed with liquid part (oil or water), creating an emulsion which is dosed directly on mixer to produce more biscuits.

The system consists of a hopper for the dosing of oil or water, manual loading of biscuit scraps, breaking and production of emulsion inside the tank, conveyance to liquid hopper and dosing on mixer. The tank can be heated or double-jacketed depending on the fat or oil that is used and is completely automated with PLC and HMI screen.

No loss of food properties, fully customized and suitable to variable production volumes.

Features & Technologies

-

Fully automated

-

Sustainable

-

No loss of food properties

-

Breaking and mixing in stainless steel tank with agitator

-

Manual loading of biscuit scrap

-

Conveyance of emulsion with volumetric pump

-

Fully customized and suitable to variable production volumes

-

Stainless steel

-

Weighing in real time, integrated automation and full traceability