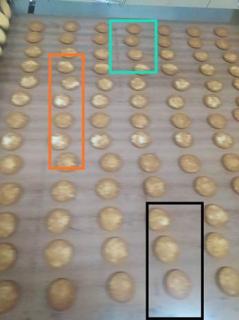

Steel Band Stickiness Greasing Problem

We are the manufactures of chocopie, we face sickness issue in our steel band while running the base cake. Can you please suggest the process of steel Band Waxing to eliminate sticking?

We tried band releasing oil , found increased in diameter of the base cake.

The Biscuit People Academy is expanding its global reach by offering world-class technical courses specifically for Spanish-speaking industry professi...

Digital monitoring transforms food safety—ensuring quality, compliance, and brand protection across the cold chain.

Discover new Biscuit People Academy courses: AI basics in English & advanced process controls for biscuit production in Portuguese.

Dectyl XMD is a conveyor belt designed for food safety. If it ever breaks and fragments end up in your product, those pieces can be detected by X-ray...

Devido à demanda esmagadora, resta apenas um número limitado de ingressos para a Biscuit People Conference (BPC) 2025, o principal evento dedicado à i...

The score is based on the number of created courses at BPA (150 points per course), the number of the lectures given at BPC (100 points per lecture), published articles (20 points for every approved article in Our Experts category ), number of resolved questions (10 points for every resolved question) and the number of asked questions (5 points for every asked question). The list is showing only top 10 biscuit industry experts.