struggling to source die inserts

Hi, l have been trying to source die inserts for a rotary moulder (which does not belong to me) hence blasting is not possible, this is a new product, in an attempt to tackle inconsistent extraction issues. thank you

Agriflex's dough cooling system introduces an innovative approach to dough temperature control, promising enhanced product quality and significant ope...

AmDough is a high-performance, truly endless woven belt from Ammeraal Beltech, designed for efficient and hygienic biscuit dough extraction with excep...

Arla Foods Ingredients has expanded its distribution partnership with MasterSense to deliver cutting-edge nutrition solutions to Chile’s fast-growing...

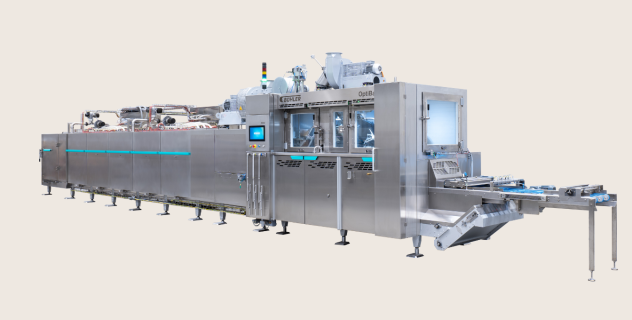

Bühler Group introduces OptiBake, the world’s first inductively heated wafer oven—cutting energy use by up to 50% and setting new standards in quality...

IPCO will use IBA 2025 to focus on the production benefits of its Rotoform rotary drop depositor, and will have a demo unit in operation on the stand.

The score is based on the number of created courses at BPA (150 points per course), the number of the lectures given at BPC (100 points per lecture), published articles (20 points for every approved article in Our Experts category ), number of resolved questions (10 points for every resolved question) and the number of asked questions (5 points for every asked question). The list is showing only top 10 biscuit industry experts.