Sternzym LQ 4020 SF

Key Features

- Homogeneous wafer batters for an improved processibility

- Reduced viscosity for a trouble-free production

- Reduced water addition for energy savings

- Waste reduction for cost savings

Description

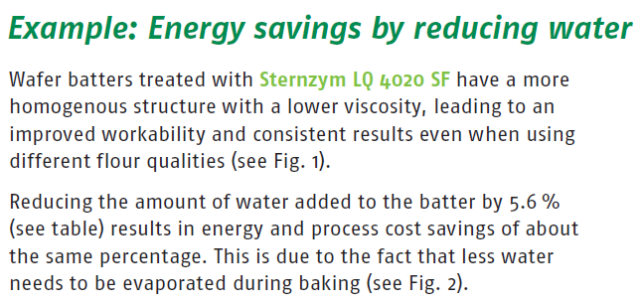

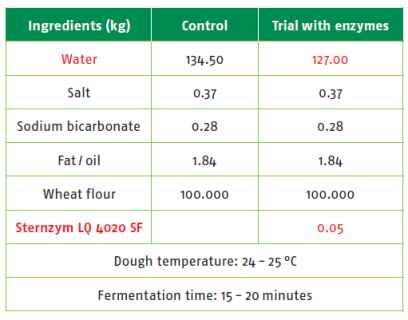

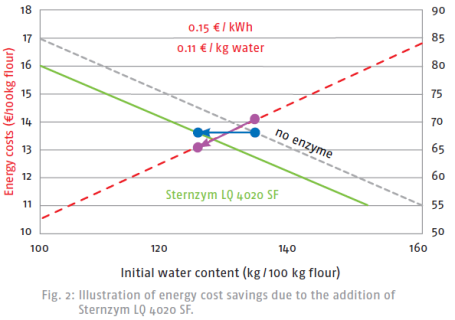

Wafer manufacturers are often forced to use different grades of flour, so the right composition of additives is becoming increasingly

important. Sternzym LQ 4020 SF ensures a consistent product quality, even with poorer flour grades, enabling a continuous

and trouble-free production. The surface appearance is enhanced and uniform browning is assured.

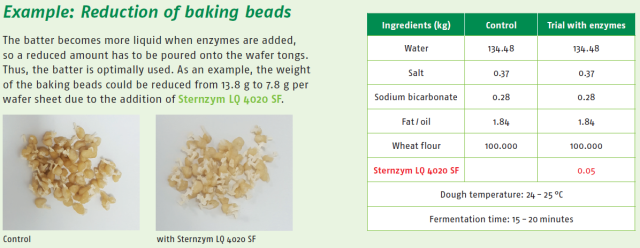

Sternzym LQ 4020 SF can be used to produce high-quality wafers, and can be used in organic products. Furthermore, it improves the

wafer production process by preventing clogging of sieves and pipes. A lower viscosity also means that less water needs to be

added to the batter, which in turn means that less energy is required for its evaporation.