Sternzym LQ 15080

Key Features

- Utilisation of high extraction flours

- Homogeneous wafer batters for an improved processibility

- Reduced viscosity for a trouble-free production

- Reduced water addition for energy savings

Description

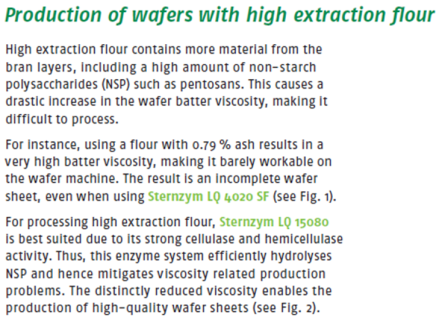

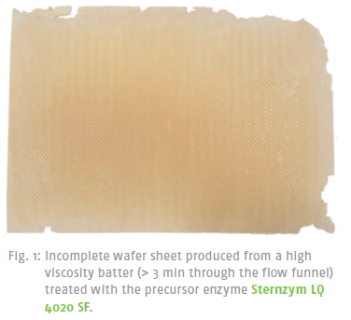

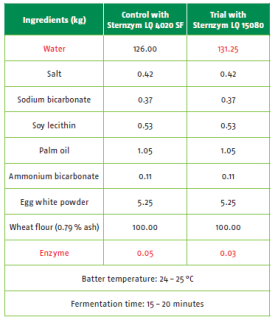

In an increasingly competitive environment, margins are always under pressure. Profitability is greatly enhanced by even marginal

improvement of flour yields, resulting in a competitive advantage. The target is to achieve maximum flour yield with acceptable

flour ash and quality, without compromising the production rate. However, higher flour yield is often associated with an increased

ash content in flour, making it inferior for wafer production. In this case Sternzym LQ 15080 is the best option to ensure a consistent

product quality, even with poorer flour qualities, enabling a continuous and trouble-free production.