Mixer type RMN

This mixer type is manufactured only in the “INOX” version, that is to say with the main chassis made of 304 stainless steel.

Tilting of the mixing bowl by means of mechanical devices, maximum tilting equal to 135° for the total discharge without the need of operator intervention.

Unless specifically requested by the customer, our mixers are managed by the operator by means of HMI and PLC.

The mixing bowl, manufactured completely in 304 stainless steel, is equipped as standard with a jacket for the heating or cooling of the dough by means of liquid circulation and on the external side it is thermally insulated in order to avoid the formation of condensation.

The production range of the mixers starts from 250 [kg/batch] up to 1.800 [kg/batch].

Total absence of protection panels and absence of dangerous moving mechanical parts. Moreover, all the surfaces are washable, in view and it is not necessary to disassemble any bulky component in order to thoroughly clean the mixer at the end of the work cycle.

Available options:

- Front and rear tilting of the mixing bowl (135° front side, 90° rear side);

- Stainless steel manufacturing, i.e. also the chassis of the mixer is fully manufactured in 304 stainless steel;

- System only for the drainage of cleaning water of the mixing bowl;

- Cleaning system of the mixing bowl and water drainage;

- Mixing bowl in 316L stainless steel.

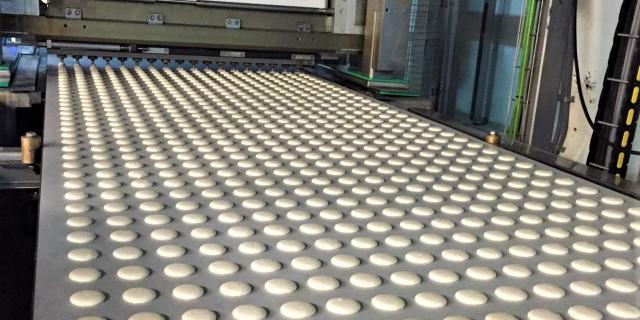

The mixer type “RMN” is also available in the "light" version called “RMNL” for the production only of soft dough, rotary moulded dough, wire-cut dough, deposited biscuits, etc.