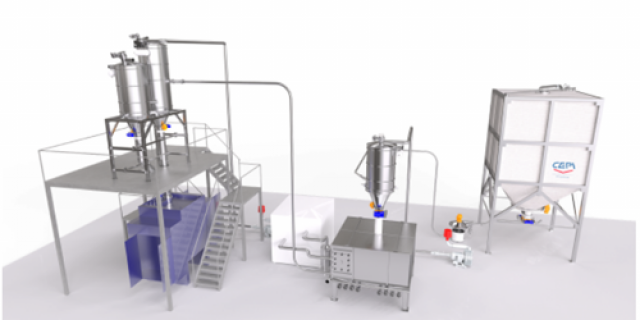

Sugar mill

System for the grinding of crystal sugar with automatic feeding, and storage tank with stirrer to avoid build-up of product and facilitate its discharge. Sugar mill enables you to create an always fresh and controlled product in complete independence, tailored to the particle size and quantity requirements of each production.

The system is provided with safety devices such as anti-explosion hatch and quench valve, and comes with dust recovering filter. Completely hermetic. No leakage in the surrounding environment thanks to the air recycling system. Sugar cleaning by means of in-line sifter and magnet detector upstream of the mill further guarantees safety and hygiene.

Features & Technologies

-

Storage tank with motor driven agitator

-

Anti-explosion hatch

-

Sugar feeding hopper

-

Quench valve

-

Dust Free

-

Multiple extraction

-

Can receive crystal sugar directly from indoor silos by means of inline sifter

-

Weighing in real time, integrated automation and full traceability