Packaging

Tray accumulator :

The accumulator manages flows between two machines

For example it separates the operation of the primary packaging zone from the secondary packaging. Even if the secondary packaging stops, the primary packaging machine can continue to operate with the same capacity. The secondary packaging machines then operate at a slightly higher rate to absorb the accumulated products.

We can provide different types of buffers depending on the needs and configuration of the lines. Some technologies allow optimizing the space in height or in length, others allow to reorganize the products in the same operation… the key issue is to ensure independent product flow between two machines.

The principle of the u-shaped accumulator for bare products can be completely considered with pallet conveyors instead of belt conveyors. In this case it is composed of 2 pallet conveyors and a 180° curve mounted on a mobile carriage driven by a Brushless motor. The variation of the accumulation capacity is carried out with the displacement of the curve.

The principle of the U-shaped buffer for unpackaged products can be designed with pallet conveyors instead of conveyor belts. In this case, it consists of 2 pallet conveyors and a 180° bend installed on a mobile carriage driven by Brushless motor. The storage capacity is given by the extra transfer length between the shortest and the largest travel, according to the buffer stroke (minimum & maximum position of the 180° bend).

Tray loading systems :

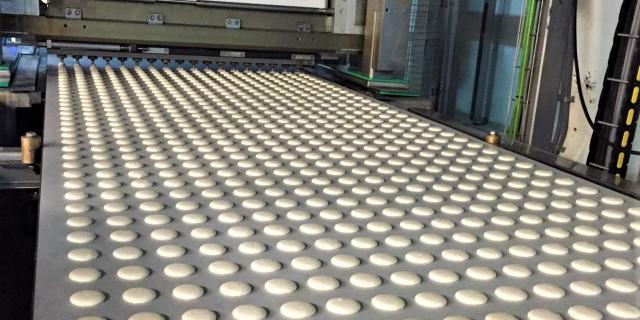

Creation of product batches using pick and place devices or robots.

For example (see drawing below), three products can be stacked continuously (brown, blue, yellow). Depending on size of product and level of complexity, the system can handle up to 120 rows per minute. Products are picked using either claws or suction and can be loaded onto trays or directly into packaging machines.

When products arrive in a disordered way, the best solution is an automated system of prehension linked to a viewing system in order to locate the position and orientation of each product on a continual basis. The system will then pick and place in tracking mode to rectify the passage.

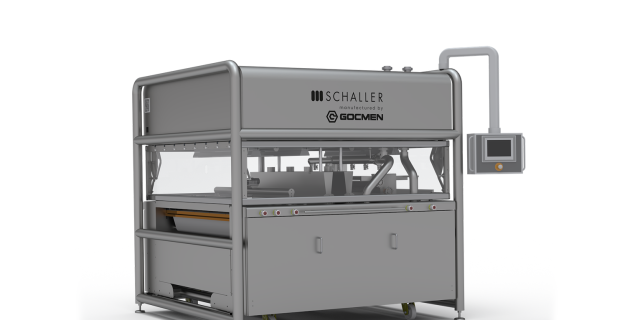

Tray denesters :

Procys offers several types of tray denesters for the complete range of trays, capacities and applications. We will discuss with you the most appropriate system for your production requirements.Main advantages:

- large autonomy,

- horizontal store,

- motorized lanes to facilitate loading.