Hard & Soft Biscuit Systems

Our Thomas L. Green brand supplies innovative, reliable and cost effective biscuit equipment.

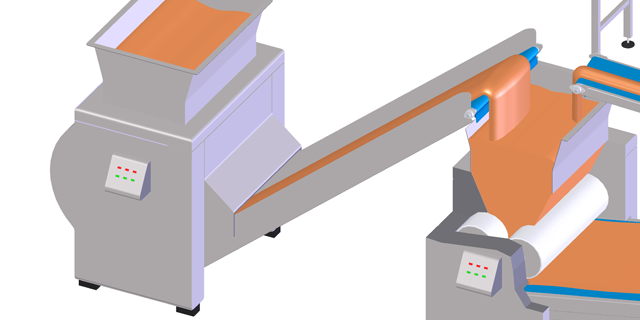

Our production systems create a variety of sheeted and rotary molded biscuits and have the flexibility to integrate batch or continuous mixing.

Production volumes range from 500 – 2500 kg/hr.

The Thomas L. Green 3-Roll Sheeter generates a consistent dough sheet ready for further thickness reduction. The Gauging Stations then ensure a gentle reduction in sheet thickness prior to shape forming. Scrapless geometric shapes and distinct cracker shapes can be formed by the Rotary Cutting Station.

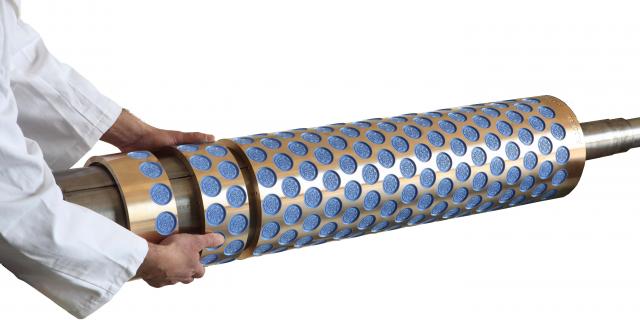

The Cutting Station accurately and continuously cuts product shapes out of a single dough sheet. All Rotary Cutter die rolls are easily and quickly changed for increased product flexibility and decreased production down time.

The Rotary Moulder is designed to efficiently produce high definition, three dimensional biscuits, cookies, sandwich cookies, bars and pet treats.

The interchangeable die roll is made of engraved brass and can be supplied with segmented rings for multiple shapes.

The machine is built on lockable casters providing portability and interchangeability with existing production line components.

The PRISM OVEN is a single-pass, flexible baking platform designed for balanced and consistent baking of a wide variety of biscuit products.

Control of the exhaust, air temperature and circulation velocity allow the operator to control the product moisture removal for maximum quality assurance.

(610) 693-5816