Rotary moulding machine

Models type R and RDZ belong to the branch of small rotary moulding machines with baking trays.

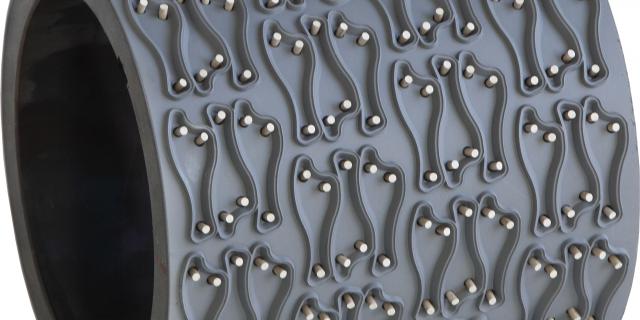

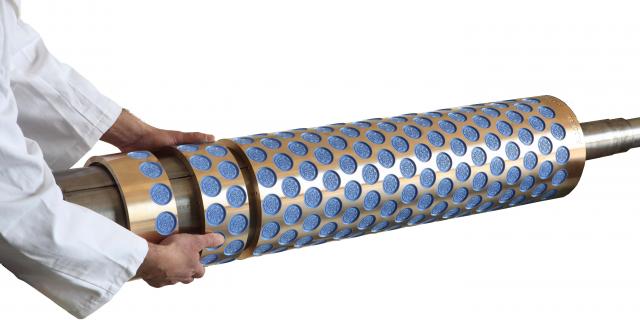

Models type R are suitable for satisfying production requirements of artisan confectioneries as well as of small/medium biscuit factories. The machine is equipped with automatic centring of biscuits on baking trays and with a system of quick roller replacement. The speed can be adjusted by means of a gearmotor controlled by an inverter. Cotton belt can be automatically cleaned and also dough scrapers are automatically evacuated by means of a motorized belt.

Models type RDZ can be considered as a variant/ evolution of models type R, and differ from these ones as they include a washover unit, a sugar sprinkler and/or a nuts sprinkler for small quantities of products (sesame, minced nuts, granulated sugar etc…). Each device can automatically recover exceeding product by means of a motorized belt.

The range is completed by models type RFN, suitable for small tunnel ovens having working widths from 500mm to 800mm.

With regards to rotary moulding machines suitable for medium and big industrial productions, Padovani rotary moulding machines can be ranked at the highest levels thanks to the automatic systems for tensioning and centring of the belt, the indipendent motorizations (two or three on customer’s specific demand) controlled by a “touch screen” panel, knives made of case- hardened and rectified stainless steel and the accuracy of the overall manufacturing.

The possibility of providing these machines with accessories such as washover units, sugar/salt sprinklers or dosing units already conceived for integrating the line, is easy and quick.