Pack 403 horizontal flow wrapper

Application information

With years of experience in the horizontal flow wrapping market, the Pack 403 high-speed flow wrapper is easy-to-use and offers intuitive operations and reproducible changeovers. In addition, the machine and the HMI are perfectly aligned for a user-centered experience.

The perfect fit

The Pack 403 mechanics and controls are configurable to your specific application and can be set for semi- or fully automated medium- to high speed wrapping. It stands for reliable and safe operation for 24/7 production environments. It’s user-centered design stands for ease of operation

as well as simple changeovers reducing operator errors.

Products

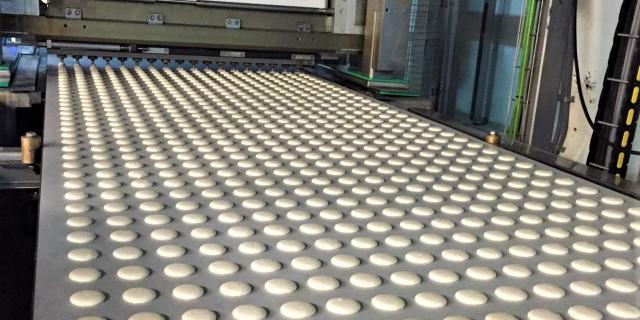

The Pack 403 is a high-speed, narrow horizontal flow wrapper and therefore is ideal for wrapping bars, bakery goods, chocolate, cookies and crackers.

Reliable, highly efficient operation

A robust, full-servo control design provides a high level of operational performance and long machine life. Depending on product characteristics, size and package format, the solution can produce up to 800 quality packages per minute.

Machine operation redefined

With its ease of set up and access, procedures overseen by a user-friendly HMI, decals, and laser-engraved scales and instructions, operators will be delighted with this machine. From clearly marked changeover parts to tensioners and finwheel pressure gauges that are visually easy to control, this is truly a user-friendly system.

Standard features

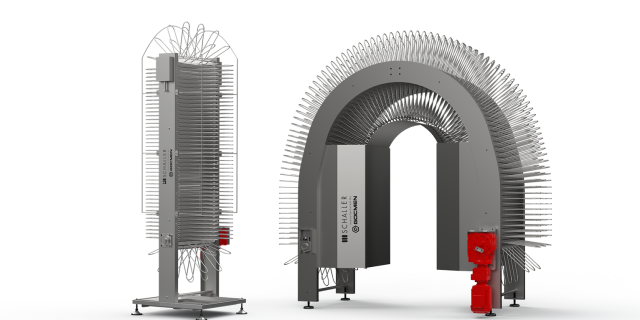

- Beckhoff controls

- Two (2) film reel holders

- Power feed roller

- Automatic film splicer

- Easily exchangeable film folding box

- Three (3) sets of finwheels built in separate

hygienic housings, 1 set heated

- 2-up crimper jaws with straight/bias knife

- Hand-wheel for manual rotating of sealing

jaws for cleaning

- 1 meter discharge conveyor with rejects for

empty bag, melted film and splices

Optional features

- Rockwell Allen-Bradley controls

- Low/almost empty film reel detection

- End of film cutting mechanism

- Film tension measuring and control

- Automatic film tracking correction

- Cold seal peeling rollers

- Pre-heating unit or 2nd heated finwheel

- Air evacuation for tighter packages

- Air or fork gusseting

- No-product-no-bag feature

- No-gap-no-seal feature

- Driven overhead roller on the discharge

- Date coders/printers

- 3-up, 4-up crimper jaws