IPCO Laser Cleaner

Bake oven belt cleaning is a maintenance task that can’t be neglected. Burnt on baking residues not only lead to a less than perfect end product but can also result in a build-up of potentially harmful acrylamide.

Traditional cleaning methods usually involve the application of chemicals, dry ice, baking release agent or detergents. All involve a great deal of manual input and usually require the shutdown not only of the line in question but also all nearby ovens, making it a dirty, time-consuming and costly process.

High power laser technology delivers dramatic reduction in cleaning time Today there is an alternative solution, one that can significantly reduce cleaning time while usually allowing production to continue on adjacent oven lines.

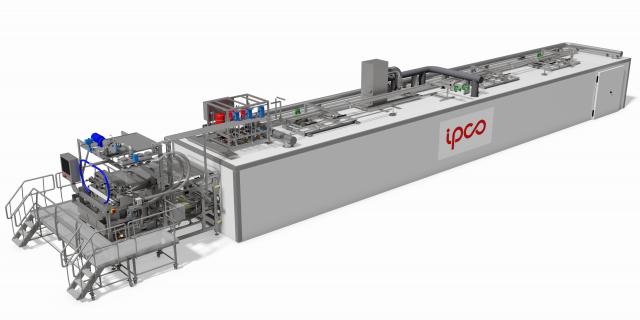

Working in partnership with one of the world’s leading names in industrial laser cleaning technology, we have developed a computercontrolled belt cleaning system that uses a high power laser to remove baking residues from the belt in a fraction of a second. The system consists of a robust, transportable industrial laser unit with high pulse power. A mobile optic allows the beam to be positioned directly above the belt. The system is equipped with an external vacuum system to extract residues and fumes.

The laser head is installed above the belt on a manually controlled carriage rail and the beam is focused on an area approximately 70 mm wide. As the belt travels beneath the laser, baking residues are removed and collected by the extraction system. Once the strip has been cleaned along the full length of the belt, the laser head is moved across to the next section.

The process is non-contact/non-abrasive and the use of a high power laser delivers stable, even cleaning across the full width of the belt on the production side, leaving the surface structure of the belt completely unaffected. The belt will be brighter than before immediately after cleaning but will quickly return to its original, even colour.

Quick, clean, green and safe

Cleaning can be carried out at a rate of between 10-15 m2 /hour. This means that – depending on belt size and level of build-up – a typical bake oven belt can be cleaned in a day, significantly faster than cleaning by hand or dry ice, which can take two days or more.

Laser cleaning is also safer, requiring no chemicals or contact with a hot belt. The elimination of chemicals and/or detergents also means that production can recommence immediately after cleaning with no waste batches. And as a completely dry process, there is no risk of rust through moisture.

Another major benefit is that cleaning can be carried out in a ‘contained’ area, so adjacent lines can usually remain fully operational. Cleaning is thorough, removing baking residues, acrylamide and grease. The result is a cleaner, more appealing and appetizing end product and easier product discharge with less sticking and wastage.

Key benefits:

• Faster cleaning – significantly faster than traditional cleaning processes.

• Contact-free – no risk, non-abrasive cleaning process.

• High power laser – no risk of belt damage (unlike ‘small’ lasers).

• Greener – no chemicals, no water, no detergents.

• Cleaner process – typically no need to close down adjacent lines.

• Safer – no chemicals or contact with hot belt.

• Cost effective – less downtime / lower investment than traditional methods.

• Clean, dry process – full production can restart immediately.

• Improved product quality – eliminates belt stickiness for cleaner product discharge.

Belt cleaning is a dirty business. So leave it to IPCO, your partner in productivity The innovative design of our all-in-one laser cleaning systems means the entire process can be managed by a single IPCO engineer. We supply everything needed to complete the work including air compressor and industrial vacuum cleaner, leaving you free to concentrate on your bake business.