New Era Machines

Send inquiry

Gauge Rolls

Gauge Roll Units deployed to reduce sheet thickness in progressive stages before cutting. The number of reduction stages is decided as per product or capacity requirements.

Application:

- Hard dough biscuits

- Crackers

- Various varieties produced/processed using Rotary Cutting

- Process

Salient features:

- Pair of Ground Rollers - 400mm diameter heavy duty

- Gap Between Rolls adjustable

- Individual Drive Motor for Each Roll with variable speed setting

- Individual Side to Side Gap Adjustment by two independent Servo Motors with Position feedback.

- Rolls foreseen with scrappers with catch tray

- Modular Unit with Delivery Web

- Hygienic Design

Options:

- Water Circulation in Rolls

- Motorized Roll Gap Adjustment

- Sheet Thickness Measurement System

- In Feed Loop Control

- CE/UL Certification

Controls:

- PLC System with Centralized HMI display

- Recipe Management System

- Optical Linear Encoder for Precise Gap Feedback & Control

- Digital Gap Readout

Size variations:

- ECM 300 Guage Roll

- GRM 300 Guage Roll

- ECM 400 Guage Roll

New Era Machines

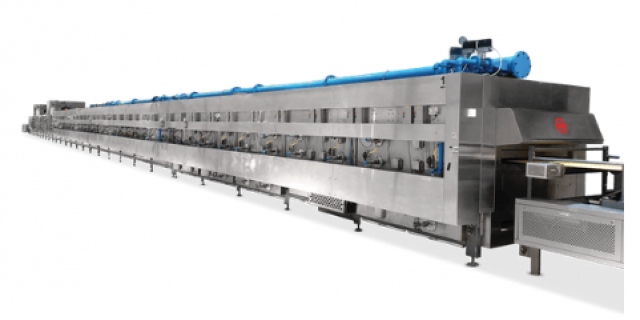

Direct Gas Fired Oven

New Era manufactures a complete range of baking ovens including direct gas fired, direct and in-direct forced convection and in-direct radia...

New Era Machines

Indirect Radiant Cyclotherm Oven

In-direct heated. Heat transfer through radiation of energy from radiator tubes above and below the band.

Product application:

Soft...

New Era Machines

302 Series Rotary Moulding

Rotary Moulding machine for producing biscuit shapes of soft dough varieties, applicable for biscuits and cookies.

Salient features...

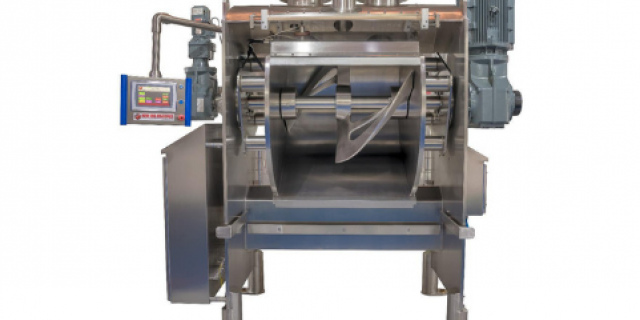

New Era Machines

Mixers

New Era Mixers range from 70 Kg up to 1200 Kg of Dough.

Features:

High Speed, Horizontal Dough Mixer

Stainless Steel D...

Related products

View all

IMA FLX HUB

Packaging Line for Biscuits in Pile

The packaging system consists of conveyor belts, vibrating channels, feeder Flowbiscuits to pile biscuits and the flowpack machine PANDA RED...

Zeppelin Systems GmbH

Codos NT - Continous mixing and kneading systems

CODOS® NT: WAS MADE FOR THE BIG JOBS

The CODOS® NT also processes large quantities of dough. The continuous mixing and kneading s...

Reading Bakery Systems

LDX Continuous Mixer

The LDX Continuous Mixer combines all ingredients except flour in the creme-up stage. In this stage, special mixing elements cut the fat int...

CEPI Spa

3 in 1 station

The 3 in 1 (weighing, filtering, blending) weighs the ingredient, separates air from product during pneumatic transport and at last blends,...