Solid Steel Belts

Solid steel bake oven belts

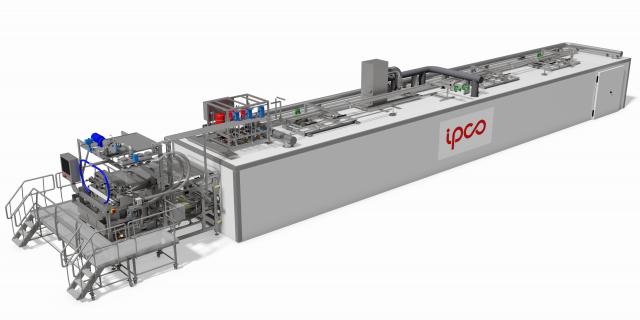

IPCO is the world’s largest manufacturer of solid and perforated steel bake oven belts, designing and supplying efficient conveying solutions to oven builders and end users, and supporting them through a global service network. And the company has been doing this since the 1920s.

A steel bake oven belt is an extraordinary tool: no other material offers such a broad range of qualities. Not only does it deliver reliable operation in applications where temperatures can reach as high as 400°C, but it does so with outstanding reliability – a 20+ year working life is far from unusual.

Solid steel bake oven belts deliver exceptional performance in terms of bake quality. Much of this is due to the excellent heat transfer and thermal conductivity of the belt, but its stability is also key: a solid or perforated steel belt keeps its shape and stays flat as it passes through the intense heat of the oven, resulting in consistent product quality.

A bake oven belt offers a number of other key production benefits too. For many users, the major advantage of steel bake oven belts has been their versatility: they can be used for products as diverse as biscuits, brownies, crackers, pastries, energy bars, part baked bread, sponges, all-butter cookies, pizza bases and more. This factor alone has convinced a number of major bakeries around the world to upgrade from mesh belts, enabling them to broaden their ranges and enter new markets.

Ease of cleaning for maximum hygiene

Steel belts are inherently hygienic in that there is nowhere for dirt to hide. The fact that they are completely smooth and flat makes them easier to clean than other belt materials.

This hard, flat, smooth surface also ensures clean product release with minimal risk of damage to fragile goods. This quality also means that a steel belt stays cleaner for longer, lessening the risk of product burning onto the belt and impacting on the quality of subsequent products.

Low maintenance means more production

Low maintenance and a long working life are important factors too. During the baking process the steel belt is placed under considerable thermal stress as heating and cooling takes place every time it completes a revolution. A combination of steel belt grade and special manufacturing phases is used to achieve the necessary thermal properties of the material.

These properties give steel belts the durability to operate for decades under what are severely challenging processing conditions. In fact it is virtually unheard of for such a belt reach ‘end of life’ due to fatigue stress.

Energy efficient

A solid steel belt will also reduce energy loss compared with other conveyor materials. Solid steel belts are lighter than wire mesh – perforated steel belts lighter still – so cost up to 30% less to heat. Each time the belt exits the baking chamber, it begins to cool and has to be heated up again so the savings are continuous. As much of 25% of an oven’s energy consumption is needed to heat the belt, so the savings can be considerable. This weight advantage also means less energy is needed to ‘drive’ the belt through the oven.

Summary of benefits

· A working life of 20+ years is not unusual.

· Excellent product support for a wide range of baked products – biscuits, pastries, sponges and bread.

· Hard smooth surface for clean product release.

· Hygienic and more easily cleaned than wire mesh belts means less down time.

· Excellent heat transfer.

· Excellent thermal conductivity for good baking performance and consistent product quality.

· Faster belt speeds increase production output.

· No stretching, good tension and tracking characteristics mean lower maintenance vs wire mesh belts.

· Less energy needed than heavier wire mesh belts, lowering production costs.

· Easy cleaning for minimal downtime.

· Wide belts up to 3 500 mm for maximum productivity.