Cookie Capper

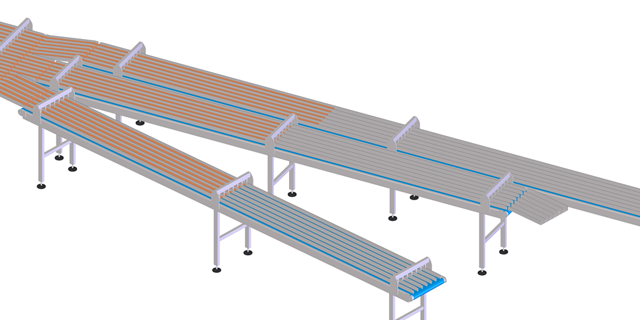

Cookie Capper is an efficient automated device designed for the production of sandwich cookies. It boasts several advantages, ensuring uniform and clean sandwiching, precise weight control, and high levels of automation.

1. Uniform and clean sandwiching: The Cookie Capper guarantees even distribution of fillings in every sandwich cookie through advanced technology and precise craftsmanship. It ensures that each cookie is free from impurities or residues, offering consumers a consistent texture and pure flavor experience.

2. Precise weight control: The equipment is equipped with a high-precision weighing system, ensuring that the weight of each sandwich cookie adheres to the set standards. This level of precision enhances product consistency and quality, meeting customer demands for standardized products.

3. High levels of automation: The Cookie Capper's automation capabilities enable efficient production of sandwich cookies. It utilizes advanced mechanical systems and programmable controls to facilitate a fully automated process, from cookie production and filling to sealing. This not only enhances production efficiency but also reduces the need for manual labor, minimizing human errors and labor costs.

4.High production capacity of up to 150 rows of sandwich cookies per minute: The high-speed production capability makes it an ideal choice for large-scale production of sandwich cookies. With the ability to produce 150 rows of sandwich cookies per minute, it contributes to improving the competitiveness and profitability of businesses.

‣www.sinobake.net

‣Email: info@sinobake.net

‣WhatsApp: 0086 13794640490 Atom