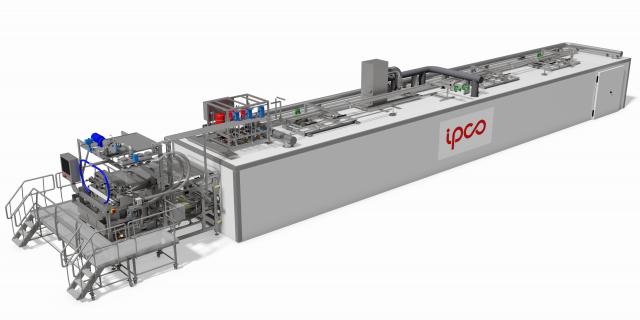

Pack 301 LS horizontal flow wrapper

Application information

Products

With the continued growth and product diversification in the global biscuit market, flexibility and adaptability are becoming critical factors for success. The Pack 301 LS (Length Slug) flow wrapper addresses exactly those

variables combined with premium product quality. The machine is ideal for handling round, rectangular, square and sandwich biscuits.

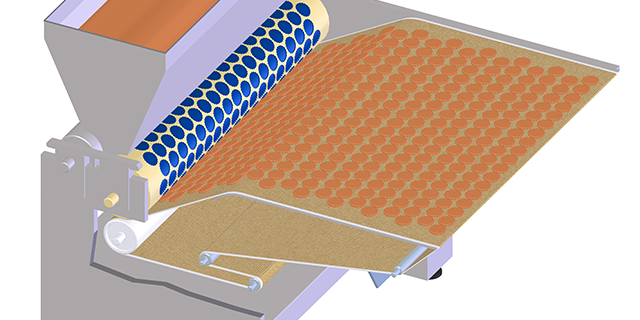

Reliable biscuit handling

Innovative features ensure an optimal product control throughout the packaging line: from the moment products are loaded into the cross chain until the package is sealed. The full servo-controlled product transfer from

the cross chain into the wrapper’s infeed chain features pre-acceleration. This allows for an optimal synchronization between the transfer unit and the infeed chain, eliminating impact on the product and maintaining product

quality.

High flexibility

High layout flexibility offers manufacturers a configuration according to their specific needs. The modular design enables scalable solutions, facilitating easy expansion of production capacities and an increase in the level of

automation from hand loading to fully automated loading. The Pack 301 LS can be provided as an integrated system including all required upstream equipment such as vibratory conveyors and measuring or counting loaders, e.g. the Smart Measuring Loader from Bosch.

Total Productive Maintenance

Designed with operator friendliness and Total Productive Maintenance in mind, the solution has been laid out to be accessed from all sides for fast changeovers, easy cleaning, and low maintenance effort. The open design

allows crumbs and rejected products to fall through or be removed easily. All of these features add to operator friendliness and boost machine uptime and availability.

Standard features

▶ Easily adjustable counter holding pins in infeed chain

▶ Quick set-up tools for fast changeovers

▶ Cross chain with easily adjustable retainer bars

▶ Simplex operation

▶ Fully servo-controlled transfer unit

▶ Two (2) film reel holders

▶ One (1) easily exchangeable fixed folding box

▶ One (1) set of rotating crimper jaws

▶ Three (3) sets of finwheels built in separate hygienic

housings

▶ Side chains to support the slug in the film tube

▶ Temperature control via separate controls on electrical

cabinet

Optional features

▶ Duplex operation

▶ Product measurement unit to detect incomplete slugs on

the cross chain

▶ Continuous crumb removal and discharge of incomplete

slugs from the cross chain

▶ Pre-acceleration transfer unit

▶ No product - no cycle feature

▶ Almost empty film reel detection

▶ Automatic film splicer (with knife)

▶ Servo controlled power feed roller

▶ Side belts to support the slug in the film tube

▶ Mechanical or air gusseting

▶ No product - no bag feature

▶ No gap - no seal feature

▶ Air reject of incorrect and empty packages

... and many more