Jacob van Kogelenberg

JKConsult

40 years experience in packaging

400 biscuits

Show User Info

Bio

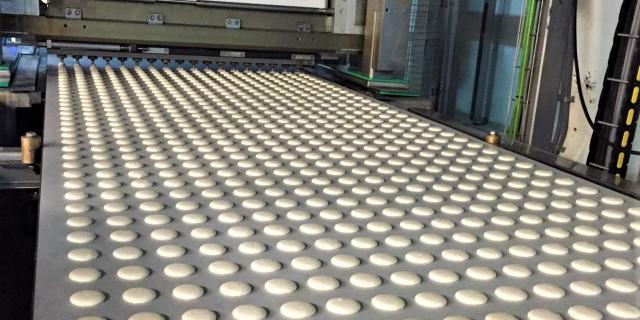

Jacob van Kogelenberg is a mechanical engineer with additional business administration training and has 40 years of experience in the packaging machinery industry. I have worked 15 years with Tevopharm Schiedam, Netherlands, building flow wrap and roll wrap machines with automatic feeding equipment, a few years in Brazil for Klöckner Hänsel do Brazil building the same type of equipment, and after a short period in bottling equipment, 16 years for SIG ( Schweizer Industrie Gesellschafft), later Bosch Packaging Systems in Beringen, Switzerland. That company again is leader in high speed packaging equipment for biscuits, chocolate, granola bars, but also stick pack and sachet for powders and cartoning equipment for these packs. Since December 2012 I am an independent consultant.

Based on my experience with gas flush packaging of soft bakery products I have given seminars at the University of Wageningen on packaging of bakery products.

I have been in charge of installation and commissioning of packaging systems for biscuit products in the UK and USA, an experience that has given me insights in the real world of handling and packaging biscuits, chocolate and granola bars and other products.

Having worked in the design of equipment, but also in the installation, sales and product management as well as in management functions and managing Director I have gained a holistic view of the business relating the different aspects.

Achievements

Keynote Maestro

Master Wordsmith

User points

Biscuits 400

Resolved questions 10

Tech talks questions 10

Published articles 180

Conference lecture 200

Biscuit People Academy 0

Articles

Jacob van Kogelenberg

wrote article

09 November 2021

Automated OEE, Industry 4.0

OEE is not a simple single number. Your OEE may look good but looking inside it may show a differentiation that tells where there are opportunities for improvement.

Jacob van Kogelenberg

wrote article

28 September 2021

How to Start Measuring OEE and Define What and Where Are Your Problems?

If you embark on the trip to get to the best level OEE, it will affect Everything in your company. It is a process that not only involves Production, also engineering and maintenance, also sourcing, P...

Jacob van Kogelenberg

wrote article

19 August 2021

Where to Start With the Overall Equipment Effectiveness?

How to measure overall equipment effectiveness and where to start? Find an explanation and checklist for the 5S method.

Featured products

CEPI Spa

GLOBOSILO

Modular, customized and made in stainless steel, hundreds of our silos store and protect materials such as flour and sugar in food installat...

Procys

Dough depositor

Procys gives you the possibility to dose sponge cake, macaroon, “boudoir” biscuits, savoiardi, pastry dough, madeleines, cake or...

Jacob van Kogelenberg

wrote article

12 August 2021

How to Find the Optimal Packaging for Your Product

Packaging is one of the largest cost factors. Developing the optimal combination of pack style and material is a challenge.

Jacob van Kogelenberg

wrote article

17 May 2021

Where to Start Mending: 5S and TPM - What Can OEE Do for You?

TPM and 5S as the methodology to improve the performance of your production line, resulting in a higher OEE

Jacob van Kogelenberg

wrote article

27 August 2020

Challenges to Management

What are the challenges managers face today? Common Management Challenges and How to Overcome them.

Jacob van Kogelenberg

wrote article

29 July 2020

Training and Education

Why training and education in the food industry are important when we speak about effectiveness?

Jacob van Kogelenberg

wrote article

07 July 2020

Center Lining and SMED

What is a center lining and how do you centerline a process? Find out how to develop your own Single-minute Digit exchange of die (SMED)?

Jacob van Kogelenberg

wrote article

07 April 2020

What Can OEE - Overall Equipment Effectiveness - Do for You?

It is important to understand fully the concept of OEE. That achieved, is will be clear what information is required to calculate the OEE and it will become clear which are the drivers, and which are...

Featured companies