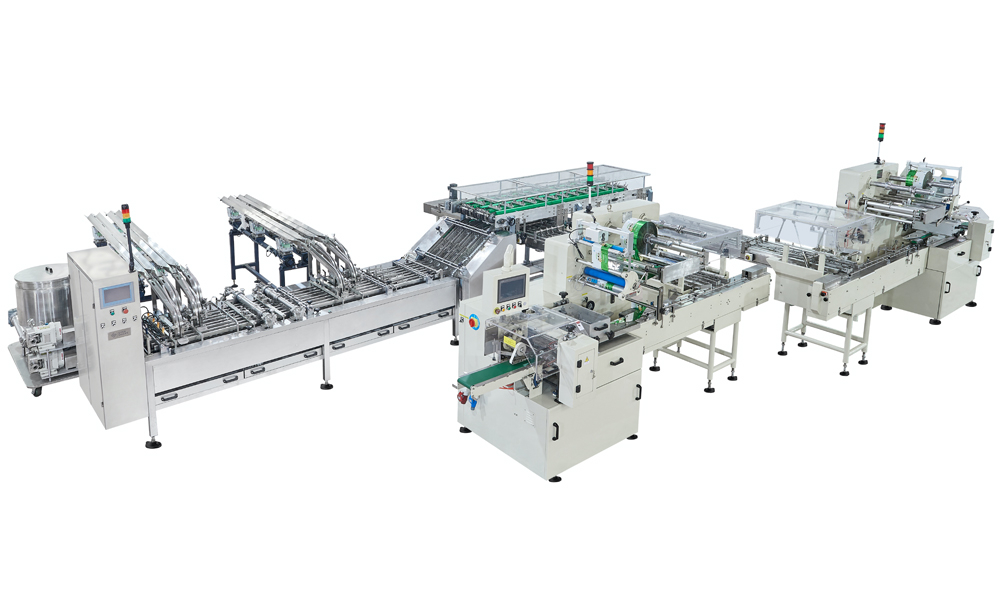

Sandwiching Automatic On Edge Packaging Line

ISM Cologne 2026 united 1,790 exhibitors and 32,500 visitors, highlighting a shift toward functional biscuits, sustainable sourcing, and integrated ma...

ISM 2026 sets new benchmarks with 1,600+ exhibitors from 74 countries. Explore the new "ISM Ingredients" platform and functional trends in biscuit ind...

The Biscuit People Academy is expanding its global reach by offering world-class technical courses specifically for Spanish-speaking industry professi...