New Era Machines

Send inquiry

Vertical Laminator

Vertical Cut Sheet Laminator comprising of a 5 Roll Sheeting machine. This machine is deployed in a cracker line to produce a laminate of multiple sheets of specified thickness stacked one on top of each other.

5 Roll Sheeter Comprising of:

- One Pair of Grooved Sheeting Rollers on Top

- One pair of Ground Gauge Rollers on Bottom

- One Grooved Sheeting Roller for Scrap on Top

- Gap Between Rolls adjustable

- Individual Drive for Each Roll

- Customized capacity of Stainless Steel Receiving Hopper

- Receiving Hopper is partitioned to keep scrap isolated from fresh dough.

- Closed Loop Pressure Measurement in Compression Chamber with speed control for top pair of sheeting rolls.

- Scrapper with Catch trays provided on Gauge Rolls

Layering Table Assembly Comprising of:

- Receiving Web

- Servo Driven Compensation Table

- Pneumatically Actuated Knife Assembly

- Servo Driven Layering Table

- Delivery Conveyor

Options:

- Water Circulation in Rolls

- Motorized Roll Gap Adjustment

- Sheet Thickness Measurement System

- Dough Level Control in Receiving Hopper

- CE/UL Certification

Control:

- PLC System with HMI display

- Recipe Management System

- Digital Gap Readout

New Era Machines

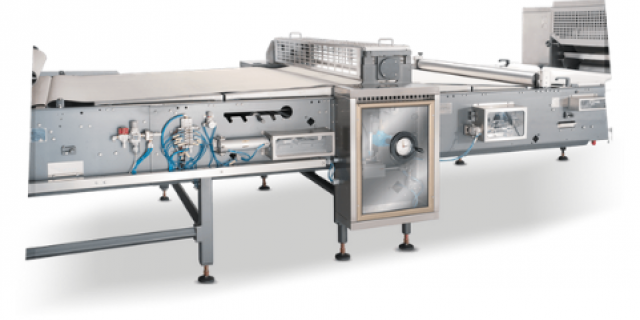

Indirect Radiant Cyclotherm Oven

In-direct heated. Heat transfer through radiation of energy from radiator tubes above and below the band.

Product application:

Soft...

New Era Machines

Baking Ovens

New Era Manufactures complete range of Baking ovens including Direct Gas Fired, Direct and In-Direct forced convection and In-Direct Radiant...

New Era Machines

Single Roll Cutting Machine

Single roll cutting machine or hard dough biscuits and crackers.

Salient features:

200 mm diameter Cutting Rol

Various work...

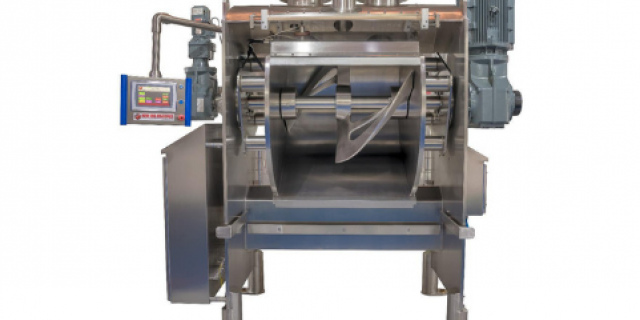

New Era Machines

Mixers

New Era Mixers range from 70 Kg up to 1200 Kg of Dough.

Features:

High Speed, Horizontal Dough Mixer

Stainless Steel D...

Related products

View all

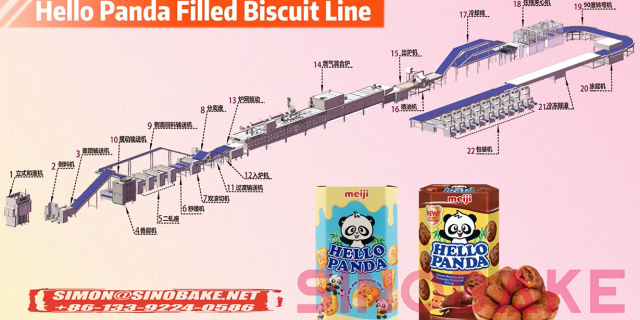

Sinobake Group LTD.

Hello Panda Filled Biscuit Production Line with Mixer Laminator Gauge Rolls and Auto Injector

Industrial Customized Biscolata Mood Filled Biscuit Production Line | 200-2,000 kg/hr: We can provide you a complete Hello Panda/ Biscolata...

Ammeraal Beltech

Duraclean

Duraclean, a synthetic belt for sticky products, offers a number of improvements for the bakery and confectionery manufacturers. Excellent p...

Miranda Automation Pvt. Ltd.

Continuous Mixing System

The key features:

Purpose: The Continuous Mixer is used for mixing hard dough and soft dough for cookies and tea biscuits....

Apinox srl

Mixer type RML

Tilting of the mixing bowl by means of mechanical devices, maximum tilting equal to 135° for the total discharge without the need of ope...