Perforated Steel Belt

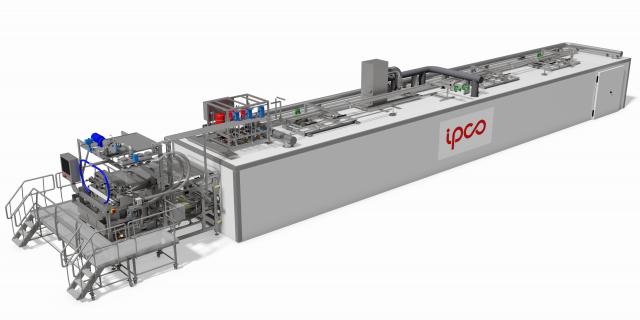

IPCO – previously operating as Sandvik Process Systems – produced the first perforated steel belts in 1935 and these versatile products have now been successfully used for baking cookies & biscuits ever since.

Today, more than 80 IPCO perforated steel belt conveyors are installed on bake ovens across the world and a growing number of operations are looking at the benefits of upgrading. This is a relatively straightforward process as a mesh belt can be replaced with a perforated belt conveyor without modifying the oven itself.

The qualities of an IPCO perforated steel belt are identical to those of the company’s solid steel belts, but with the additional versatility of being able to bake ‘mesh’ products. In short, perforated bake oven belts offer the best of both worlds. Another major benefit is a reduction in baking time.

Working life of 20+ years

The lifetime of an IPCO perforated belt will be the same as that of one of the company’s solid steel belts, typically more than 20 years. This compares favourably with the average lifetime of a wire mesh belt, which is generally 4-5 years.

Greater cleanability

One of major handicaps of wire mesh belts is the difficulty in cleaning. Perforated steel belt conveyors are flat, meaning that cleaning operations are simpler, faster and more economical, with savings in water and detergent of up to 25%. Other benefits of upgrading to an easier-to-clean perforated steel belt include:

- Greater output – reduced losses caused by product contamination

- Improved quality – residuals on wire mesh belts can result in inconsistent baking

- Greater productivity – less downtime linked to cleaning & replacing operations

Strong and stable for greater reliability

Perforated steel conveyor belts are inherently stronger and more stable than mesh. As well as delivering a much longer working life, this also means a significant reduction in maintenance requirements and improved operational performance.

- Less maintenance due to strength and resistance to damage

- Easier repair if problems do occur

- Better tracking and lower vibration for more reliable performance

- Consistent belt width (wire mesh belts suffer a width shrinking due to pre-tension)

Excellent product quality

The advantages when using an IPCO perforated belt depend on the type of product(s) being baked but the quality of many products can be significantly improved by upgrading from a mesh belt.

- Easier/cleaner removal of the product from the belt

- No deformations after baking process

- Greater consistency – elimination of variations in shape during the process

- No more craters on the base

- Cleaner products – no more contamination caused by residuals of baking process

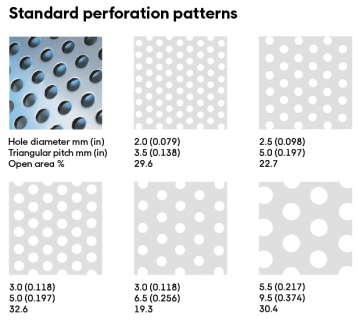

Specifications to suit all requirements

IPCO perforated belts are available in five standard perforation patterns to meet most requirements. A broad range of other patterns, with a minimum hole diameter of 0.8mm (0.03 in.) and different spacing, can be provided to suit specific applications.