Quality baking and the ‘cookie’ factor

In this article, Stefania Montalti explains how to design a dosing system that is turn-key, easily expandable and circular.

While there is a wide variety of wire cutting systems for biscuits and cookies, the following two - illustrated very schematically in the video - are...

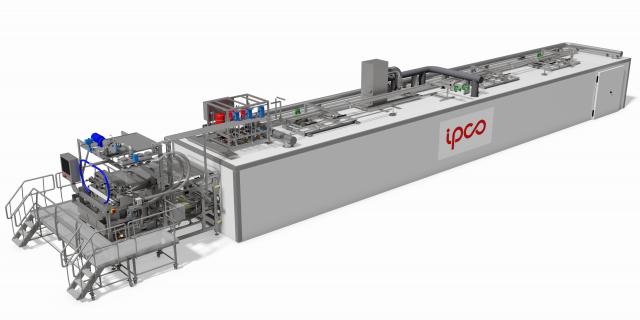

RBS oven designs offer electric heat and other solutions to reduce costs, conserve energy, and minimize emissions.